Heat Transfer Manipulation of Friction Based Braking System

All material © Copyright 2015 Adam Thomas

Design

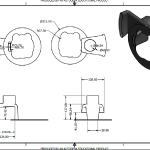

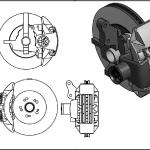

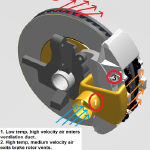

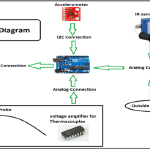

Our goal for this project was to create an inexpensive cooling system that could be easily integrated with an existing braking solution. We started with the concept that more airflow to the rotor increases cooling ability and thermal insulation of vulnerable components reduces the possibility of failure. A high flow fan with ducting was used to supply the rotor with ambient air and thermal shims were used to isolate the caliper from high temperatures. The solution is further explained in the photo gallery.

Testing and Analysis

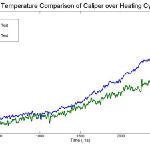

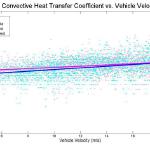

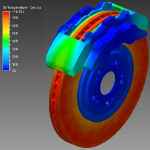

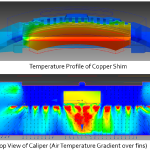

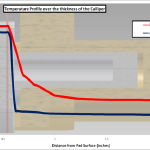

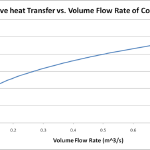

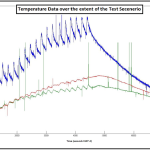

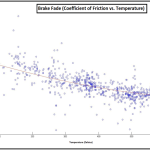

A data acquisition system was used to gather information about the thermal characteristics of the original system and upgraded solution. It was shown that the thermal shims were able to reduce the caliper temperature by about 40%. The extra airflow to the rotor increased the cooling ability at lower vehicle velocities, but as the vehicle surpassed about 50 mph, the rotors internal veins pumped more air than the fan allowed. This became a hindrance to the cooling of the rotor. A further possible solution would be to create a bypass valve that opens at higher speeds.

Final Product

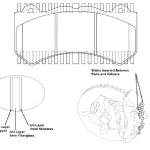

A prototype was fabricated using fiberglass and carbon fiber composites for the ducting, a high flow RC fan was used to create the air flow and a copper, fiberglass, and stainless steel shim was used to insulate the caliper.

![Rotor Temperature during Test Cycles

Three different test cycles were conducted. (1) Initial test without any fans or shims installed [red]. (2) Test with no shims installed and only the fan blowing air into the rotor veins [blue] and (3) Final test with the complete system, shims + fan [green]. Rotor Temperature during Test Cycles

Three different test cycles were conducted. (1) Initial test without any fans or shims installed [red]. (2) Test with no shims installed and only the fan blowing air into the rotor veins [blue] and (3) Final test with the complete system, shims + fan [green].](publishImages/Senior-Design-Project~~element81~~3.jpg)